For the ever-evolving landscape of production and design, the capability to adjust and change resources right into functional and visually pleasing elements is extremely important.

Amongst the diverse range of processes available, Plastic Manufacture stands as a cornerstone, offering a remarkable degree of flexibility and modification for a huge range of applications. From detailed clinical tools to robust commercial components, and from smooth consumer electronics housings to eye-catching signage, the effect of proficient Plastic Manufacture is obvious, forming the globe around us in countless means.

At its heart, Plastic Fabrication includes a variety of strategies employed to cut, shape, mold, join, and surface plastic products into wanted types. Unlike automation methods like shot molding, Plastic Fabrication often focuses on reduced volume production, prototypes, customized layouts, and larger or much more complex parts that might not be economically viable with other processes. This inherent versatility makes Plastic Fabrication an indispensable device for designers, designers, and companies across numerous sectors.

The appeal of Plastic Manufacture lies in the diverse tool kit of methods it incorporates. Knowledgeable fabricators utilize strategies such as CNC machining, where computer-controlled tools precisely reduced and shape plastic sheets, rods, and obstructs according to a digital layouts. This approach supplies outstanding accuracy and repeatability, making it perfect for complex get rid of limited tolerances. Laser reducing provides an additional exact technique for cutting complicated shapes and detailed details from plastic sheets, frequently leaving tidy and sleek sides.

Beyond subtractive methods, Plastic Manufacture also consists of formative strategies. Plastic welding, utilizing different approaches like ultrasonic, warmer, or solvent welding, permits the long-term joining of plastic parts, producing strong and smooth bonds. Thermoforming, as talked about previously with vacuum forming, involves heating and forming plastic sheets over molds, providing a economical service for developing enclosures, trays, and other contoured components. Flexing and creating techniques, usually making use of heat, allow for the creation of complicated three-dimensional shapes from plastic sheets and poles.

The selection of the ideal Plastic Fabrication method depends on a multitude of factors, including the kind of plastic material, the complexity of the design, the needed tolerances, the production quantity, and budgetary constraints. Experienced Plastic Fabrication service providers have the competence to examine these variables and advise the most reliable and cost-effective approach for each and every task.

The applications of Plastic Construction are extremely varied and continue to increase as material science and fabrication modern technologies advancement. In the medical industry, Plastic Fabrication plays a vital duty in developing custom-made implants, surgical guides, analysis gadgets, and equipment housings that fulfill rigid regulatory demands. The aerospace and defense markets depend on Plastic Manufacture for light-weight and resilient components made use of in airplane interiors, drone parts, and safety gear.

Consumer electronics profit greatly from Plastic Construction in the development of sleek and practical real estates, bezels, and interior components. The retail and signage sectors utilize Plastic Construction to generate attractive screens, point-of-sale products, and durable signage that withstands various environmental conditions. Also the building and construction industries leverage Plastic Manufacture for developing personalized cladding, skylights, and ornamental elements.

Selecting a reputable and seasoned Plastic Construction service provider is extremely important for guaranteeing the success of any kind of project. Plastic Fabrication A credible fabricator will certainly have a deep understanding of numerous plastic products and their residential or commercial properties, the abilities and limitations of various fabrication strategies, and the significance of quality control throughout the entire procedure. They can provide valuable style consultation, helping to enhance parts for manufacturability and cost-efficiency.

In addition, numerous Plastic Construction companies offer a range of value-added solutions, including finishing (such as sprucing up, paint, and covering), setting up, and even product packaging. This thorough strategy can enhance the production procedure and offer a single point of get in touch with for all your Plastic Fabrication requires.

To conclude, Plastic Manufacture stands as a vital and versatile self-control within the realm of production. Its capacity to transform a broad range of plastic products right into custom-made parts through a varied series of methods makes it an indispensable device for development throughout various sectors. As modern technology remains to development and the need for specialized plastic components grows, the competence and capacities of skilled Plastic Construction provider will certainly stay vital fit the future of product layout and manufacturing. Whether you need a single prototype or a tiny set of custom components, checking out the possibilities provided by skilled Plastic Manufacture can unlock a globe of crafted polymer services for your specific needs.

Scott Baio Then & Now!

Scott Baio Then & Now! Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Mackenzie Rosman Then & Now!

Mackenzie Rosman Then & Now! Christy Canyon Then & Now!

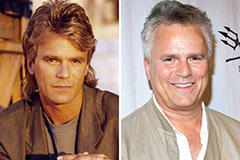

Christy Canyon Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!